News - Feb 27, 2023 Improved Management of Healthcare Waste at the Prince Ngu Hospital

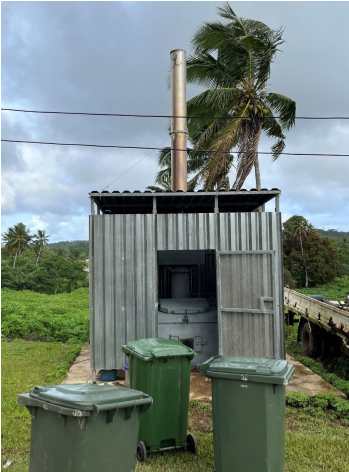

The Prince Ngu hospital on Vava’u, Tongatapu is better equipped to properly and safely manage healthcare waste after repair works to the hospital’s medical waste incinerator was completed. The incinerator is now capable of incinerating healthcare waste materials in a smoke free manner.

The incinerator was provided to the hospital, under the initial PacWaste project, had not been in use for a number of years due to the emission of a significant amount of smoke, which could not be resolved by incinerator operators.

While the incinerator was not in operation, hospital waste was taken to the Kalaka Landfill for disposal in a dedicated area.

The incinerator repair, commissioning, and operational and maintenance training was completed by PacWastePlus as part of the scope of works of the engaged contractor, Mr Michael Coccia, from Advanced Combustion Engineering.

The incinerator modifications performed were designed to bring the unit back into service and to improve reliability by rectifying several significant design and installation issues. The repair works also included installation of new burners, new controls, a higher chimney, elevating the diesel fuel tanks and putting in new diesel lines.

“We had significant concerns with the incinerator secondary combustion chamber and the secondary burner being undersized and also the incinerator design which utilised excess air from the diesel fuel burners to provide the combustion air essential to burn the waste materials”, said Mr Coccia.

“These two issues are the reason the Prince Ngu Hospital incinerator, and most likely other similar units, smoked significantly during operation.”

The contractor identified that when the primary burner remained in operation during the burn cycle, most of the available air from the burner fan was utilised to burn the diesel fuel, with an insufficient quantity of residual air available to burn the waste materials resulting in the emission of significant quantity of smoke.

After much consideration the contractor reduced the size of the primary burner fuel injection nozzle, subsequently reducing the burner combustion air demand, which was sufficient to enable the operation of the primary burner with an adequate quantity of residual combustion air available to allow the incinerator to operate in a smoke free manner.

“We have carried out the necessary repairs and conducted trial burns on the incinerator where we tried the refractory structure on a period of eighteen hours, over two trial burns and the incinerator is now burning successfully and smoke free.”

The operation of the incinerator is largely manual, whereby the operators are required to make a number of changes during the burn cycle and therefore appropriate training needed for staff was provided along with an operation manual to guide the operators on basic repair, maintenance and proper usage of the hospital incinerator.

“Training of incinerator operating staff is extremely important, especially with a plant like this. We have now trained hospital staff, which included operators, electricians, environmental officers and other hospital staff”, added Mr Coccia.

Short interview video with Mr Michael Coccia, from Advanced Combustion Engineering

“We have left incinerator spare parts, personal protective equipment for operator staff and my advice to the operators is to look after the incinerator, keep it maintained and clean, maintain things before they break down and keep training new staff on the correct way to operate and maintain the incinerator.”

According to Ms Temaleti Mausia, the Public Health Division Health Inspector for Prince Ngu Hospital, who also supervises staff operating the hospital’s incinerator, the types of wastes disposed in the incinerator included clinical wastes such as waste from treating wounds and infections, hypodermic needles, hospital syringes and other types of surgical waste.

“The hospital incinerator will be operated three times a week, but at times more depending on how much waste was produced within the hospital” said Ms Mausia.

“We would like to thank the EU, SPREP and the PacWastePlus programme for engaging a consultant to not only repair our incinerator but also for the valuable training provided to our hospital staff, and incinerator operators on how to properly operate and maintain the incinerator.”

The programme team will produce and provide to the hospital durable signage and posters on basic standard operating procedures and instructions that will be placed near the incinerator, so they are always there as reference for the operators.